Patrick Tung | X-ray vision: revealing secrets to resurrect batteries

Next time you think of throwing out your old batteries because they don’t hold a charge anymore… first imagine what other uses they could have.

Australia is rapidly shifting towards a renewables fuelled economy, and huge technological leaps in batteries are often cited as heroes of sustainability. But the knowledge acquired through high-powered X-ray tomography – a technology similar to CAT scans in hospitals – is also a key factor in creating a greener economy. When renewables like batteries reach their expiration date they could end up in landfill, but tomography technology allows us to see and understand what is inside the batteries, and repurpose the working components. So how might new innovations in tomography help us recycle and reuse complex technologies to build a circular, truly sustainable economy?

Transcript

Ann Mossop: In a world of global pandemics, climate emergencies, and ever-increasing costs of living, it's understandable that we might feel fearful about what the future holds. But as we make our way through the 21st century, there are, in fact, many new and exciting discoveries which can improve our lives. I'm Ann Mossop, director of the UNSW Centre for Ideas. Welcome to What comes next? From the potential healing powers of magic mushrooms in mental health, to how x-ray vision might help us transition to a renewable economy. In this 10-part series, we'll hear from UNSW Sydney’s brightest minds, unpacking some of the big ideas, which are integral to our 21st century challenges.

As we rapidly shift towards an economy fueled by renewables, is tomography, a technology similar to CAT scans in hospitals, the secret to unlocking an even more sustainable future? Patrick Tung has the X-ray vision we need to uncover the secrets to green technology.

Patrick Tung: The world right now is at a stage where we're embracing renewable energy solutions and moving away from fossil fuels. This is especially true with the adoption of electric vehicles, with the use of fossil fuels being replaced with these exact batteries, which allow an electric vehicle to be super fast, super quiet, but also super clean. But one aspect that is not thought of or talked about as commonly, is what we do with all these batteries after they've reached their intended lifespan. Because once these batteries degrade to about 75% of their capacity, these batteries will need to be replaced as they won't have enough power to move the vehicle properly. And this is going to be a big problem. Because there's going to be millions of these cars. With each car having thousands of these cells. We're talking about billions of batteries becoming useless for these electric vehicles, and possibly getting tossed straight into landfill.

So what comes next for all these batteries? Well, the obvious thing to do is to recycle them. But while all the materials that make up the battery are potentially recyclable, separating them out is labour intensive, and a complex, expensive process. So what else can we do with them while we're trying to optimise this recycling procedure? Well, actually, these batteries can be reused for other purposes, for things like off grid power sources, backup power use and solar powered applications. This way, the batteries are given a second life by extending the battery's usable lifespan so that every bit of energy can be squeezed out. And just to paint the picture of how useful this would be, it's projected that in the year 2030, there'll be 85 million electric vehicles sold worldwide, with the batteries having 1000 gigawatt hours of energy left in them. And to put that into perspective, only 25 gigawatts of rooftop solar panels have been installed in the history of Australia. Now that is a lot of homes those batteries could be powering by giving them a second life.

Okay, cool. So you can reuse these batteries from electric vehicles and other applications in their second life, and divert batteries from landfill and save on money. Sounds like a great solution. But then the next question is, from all these billions of batteries, how do we know which ones we can use? This question turns out to be really important, because the shiny new batteries that you put into the vehicle are not going to be the same as when you take them out. That's because they've changed from all the brutal discharging and recharging cycles, which eventually degrade the battery. But we've also seen the worst case scenario of these degrading batteries, in Samsung phones, where they've been known to spontaneously catch on fire and explode. This disaster cost 5.3 billion US dollars, to recall all those batteries. So we need to ensure we avoid these dangerous situations at all costs, by making sure we understand the overall health of the battery, inside and out. But in order to understand how these Disasters are happening on the outside, we have to delve into the battery to understand what's going on inside.

The solution we're developing at our lab at UNSW is to use X-rays, which gives us a way of seeing inside the battery and how it works without physically touching it. And these X-rays are just like the X-ray scans you get in hospitals, where you have X-rays shoot at your body, and have a detector on the other side that captures an image based on how different materials absorb these X-rays. So for example, X-rays pass right through your skin and blood vessels, but your denser bones absorb more of those X-rays, so you see that difference in the X-ray scan. For batteries, all the different materials used, such as lithium, the electrodes, and even the metal casing outside all absorb the X-rays differently and this reveals a two dimensional image that gives us a unique picture of what's inside the battery.

But at our lab, we go a dimension further by using a technique known as tomography. Now the word tomography is made up of two parts. ‘Tomo’ comes from ancient Greek, which means a slice or a section and ‘graphy’ means, to describe something by. So much like the word geography is describing something through the use of the earth, tomography is describing a material through the use of slices. And we do this by taking two dimensional images of the battery, while it's rotating in the X-rays, to collect hundreds and sometimes thousands of these images. We then combine all these slices together to make a complete three dimensional model of the battery and with this 3D model, we can then explore the landscape of the battery. However, we like; zooming in, rotating, peeling back layers, so that we're able to fully understand how every little hidden component contributes to the battery's performance, and health. And with this 3D X-ray vision, what we end up seeing are the layers of electrodes inside the battery that are rolled up to form the cylindrical shape that we see. And one of the coolest things we can do with our 3D battery model, is to take it and unroll it, virtually. This way, we can flatten out the whole round up electrode and get a clear picture, all in one glance, without touching it at all. This gives us the ability to quickly and easily explore, pinpoint, and discover any flaws or imperfections in the battery that would jeopardise its performance or health. And this would not be possible without X-ray tomography.

What we've discovered is the growth of these foreign objects inside the battery as it's being used. These foreign objects are what we call dendrites, which are one of the most insidious things that can grow and destroy a battery from within. These dendrites are microscopic whiskers that slowly grow from tiny deposits of lithium. They end up digging through the layers of the battery, which could then connect parts of the battery that shouldn't be connected, to create short circuits. And these short circuits allow a surge of electrical current that can start fires and cause those exploding batteries. Now on top of all this cool analysis we can do, we can use the same cool AI algorithms that we see in Tesla cars, used to recognize stop signs and pedestrians, to be customised to recognise all these defects automatically. And this really opens up the possibility of assessing for the most useful batteries at an industrial scale to realistically pave the way for the wave of Second Life batteries to be used in the future.

So, as we transition into a world with clean renewable energy, we'll have to consider how we're going to extract all the potential from all the technologies we're going to use to get there. And while there will be hurdles and challenges to overcome, as humans, we need to continually discover innovative ideas to solve them. But as X-rays and batteries have shown, sometimes the best way to search for that spark is by looking inside.

Ann Mossop: Thanks for coming to talk to us.

Patrick Tung: Great to be here.

Ann Mossop: How did you end up in the world of tomography?

Patrick Tung: So I think it started with my dad being an engineer?

Ann Mossop: What kind of an engineer?

Patrick Tung: Mechanical engineer. So he studied at UTS… so he immigrated from Hong Kong and then studied at UTS. He’d always have these books and textbooks all around. So I think that's stoked the fire to do something in the, sort of, STEM area.

Ann Mossop: So you did a science degree?

Patrick Tung: Yes, I did.

Ann Mossop: Were you looking at nanotechnology?

Patrick Tung: So in the bachelors, I have to be honest, I wasn't listening too much.

Ann Mossop: Yeah, like many of us… the first few years of university…

Patrick Tung: Yeah, I just didn't really understand why, I was like, you know, what was the point of learning it all. And in the final years, when I did my honours project, I was like, oh…

Ann Mossop: And so what was your honours project? Was that something where the nature of the project or the people you were working with made it more interesting?

Patrick Tung: Yeah, so I was looking at the deformation mechanisms in cortical bone.

Ann Mossop: Oh wow.

Patrick Tung: So it's a bit different to what I'm doing now. Doing these, sort of, compression tests, and then making these graphs and extrapolating things from the graphs. And then I was like, oh, we're actually, I'm actually using the things that I learned in my Bachelor’s, I'm like, oh, this is what it's for. I get it now!

Ann Mossop: It's really interesting, isn't it? This is such a common thing about people being motivated and inspired by seeing how what they're learning can be applied.

Patrick Tung: Yeah, exactly.

Ann Mossop: How did you come to be working with this incredibly interesting and, you know, widely applicable technology that we know as tomography?

Patrick Tung: Yeah, I think, so it started with the honours project, where I ended up using X-rays, to shoot at the bone to then understand the atomic structures within the bone that sort of dictate its mechanical properties. And so then, I stayed with Professor John Daniels, to do a PhD. And so that was looking at lead free, piezoelectric materials, which I…

Ann Mossop: Stop there. Piezoelectric…

Patrick Tung: Let’s wind it back.

Ann Mossop: Lead free, I can manage, but piezoelectric… tell us what that is.

Patrick Tung: So they are materials that if you squeeze them, they produce an electric voltage. And if you pass an electric voltage through them, they change shape.

Ann Mossop: And so where would we encounter piezoelectric materials in our daily life? That sounds pretty extraordinary, that sounds, kind of, almost magical.

Patrick Tung: It is a little bit. The first application I can think of is in cigarette lighters. So when you press down to like the spark, you're actually pressing down on a piece of electric material, sometimes, in the lighters, and that creates a voltage, which creates the spark for the fire.

Ann Mossop: Oh, wow.

Patrick Tung: But other things are like submarines for sonar, because you need something that vibrates really fast. So you can control the electric voltage very quickly. And things like, some very cool application is, where they put a piezoelectric in pacemakers. And so, the heart puts mechanical motion on the piezoelectric material, which then creates a voltage, which then charges the battery, which powers the pacemaker.

Ann Mossop: Amazing.

Patrick Tung: That’s crazy.

Ann Mossop: Yeah!

Patrick Tung: So yeah, I was using X-rays to also study the atomic structure of those. And then from there did a postdoc sort of transitioning, still using X-rays, but sort of in a different way, more like a hospital CAT scan, but still looking inside and trying to understand the interior of materials.

Ann Mossop: It's amazing. And so in your talk, you've shown us how we can recover batteries that have not reached the end of their useful life, but might need to be repurposed, and how we can really make much better use of the energy in batteries. But this is in a situation where we're on the cusp, particularly in Australia, where uptake of EVs is still very low. We're on the cusp of transitioning into this, you know, much more battery driven world. What kind of timeframe do you see this becoming really important in?

Patrick Tung: So I don't know in terms of Australia, but you know, there's much more of an uptake in the US and Europe, and the projected times where these batteries are useless from electric vehicles is about 10 years. So it depends on how hard you use them and all that. But yeah, 10 years is roughly when you need to replace these batteries. And so if you think about when they were first introduced, it's about time to get on top of this situation, because it's gonna be a lot of batteries.

Ann Mossop: So potentially, in Australia, we're a few years off that?

Patrick Tung: Yeah.

Ann Mossop: But given that in Northern Europe, and in the US, there's been a lot more uptake, this is the kind of thing that's really important. So is this a technology that is widely understood and used?

Patrick Tung: In terms of the X-ray tomography?

Ann Mossop: In terms of the X-ray tomography, and the situation with batteries?

Patrick Tung: Yes, the technology is definitely widespread because yeah, it's in the CT scans that we use in hospitals. And in the medical field, there's a lot of work in that pushing forward, like all the different advanced analysis and making sure that the X-rays that you get, the dosage is not too high. All the little techniques, but it's really, maybe, in the last five, I think five, years that X-ray tomography has been used a lot more on materials instead of the medical field, and being able to exploit all the different things that we can see from it. So, in terms of using it on batteries, it's still relatively new. No more than five years, I think, six years. There was a paper on this. So there's a lot of room to explore with tomography in batteries.

Ann Mossop: And what do you think accounts for this focus on materials? Is it the fact that we're needing to think much more carefully about making the most of all of these resources? Is that as a sustainability and resource conservation push? Or is it just that we reached a time when somebody said, hey, maybe we can try it on that?

Patrick Tung: I think it's a combination of these things. I think the first thing is that technology has improved enough. So in terms of the tomography on materials, it's much higher resolution than what you need for medical, because we need to see these, sort of, features inside materials that are in the range of hundreds of nanometers to micrometres. With medical tomography, you don't really need that resolution, you can sort of…

Ann Mossop: Because the human body is so simple.

Patrick Tung: Yeah. Yeah, you're gonna see a cracked bone, you can kind of just see it. But yeah, so, the technology, but also the computing power, because you need a lot to be able to handle such a large data set. Because in my talk, as I say, tomography is basically understanding material through slices. And with this higher resolution, there's a lot more data points, and we have a lot of slices. And so, yeah, computer power has sort of caught up to be able to actually handle that efficiently and easily. And so that…

Ann Mossop: So to be able to give you an answer, to tell you what it’s seeing…

Patrick Tung: And then we can start now, you know, having a lot more applications where we can use this and sort of being like, oh, you know, what can we use this for? And, oh, this is cool. And then and then working from there.

Ann Mossop: So that makes, that totally makes sense. That thing about the computing power and strain, because obviously, with some of those applications in the human body, you know, people think a major health issue for a human in a developed country is worth those kinds of resources. Whereas, you know, the conservation of a single battery, maybe not. But now if the computing power has caught up with it that makes it feasible to have that.

Patrick Tung: So it's a combination of all that, that’s allowed this.

Ann Mossop: And so this technology, I know, batteries are only one of the things that you've been looking at, and that in some ways, you look at a whole lot of different kinds of materials. What are the other things that you're doing with it?

Patrick Tung: Yeah so, working at the tomography lab, we have people coming in and, and saying…

Ann Mossop: Saying, have a look at this!

Patrick Tung: Yeah, solar cells, lots of concrete, where it's got fibres reinforcing inside, and you want to know, where those fibres are, which direction they're facing, there's cracks inside, or composite materials, and you want to know, where all the different composites are. A lot of geological things like, where we don't understand what minerals are inside and where they are, and pores and things like, for carbon sequestration, you really want to understand how carbon sort of goes through the rocks and using tomography, we can see all that inside.

Ann Mossop: Pretty amazing. And you can see that there are certainly lots of applications. So in terms of your own work in this area, the batteries, what are the next steps do you think, in terms of taking it further and making it something that is, you know, that's going to be applicable in that kind of situation? What are the things that need to happen?

Patrick Tung: I think, well, from my research, I'm really focusing, like, like many people are focusing on machine learning and applications of AI and things like that. One of the coolest things that I'm trying to work on is where, so with tomography, you usually need to take hundreds or thousands of images of the material while you're rotating it, so you get different slices at different angles, and then…

Ann Mossop: And build up this incredibly detailed 3D picture…

Patrick Tung: Yeah, and then reconstruct all that into a cool 3D model. But with AI, one of the coolest things is to be able to possibly… so they’ve done this in the medical field, to take one snapshot of the battery, and then use the AI algorithm to be able to reconstruct the three dimensional. So you sort of give it a sample to be like, you know, if I give you this image, this is the 3D model, right? Kind of like, I give you this picture. This is a dog, this is a cat. But yeah, so then you're able to, well, one, scan, you know, like really fast, and be able to extract a 3D model out of just one X-ray scan. But then that also allows you to do really cool dynamic experiments, you know, where we're charging and discharging the battery at the same time while we're collecting that image. And then we can see the changes.

Ann Mossop: And what does that allow you to do?

Patrick Tung: And then we're able to, from that X-ray image, get that full 3D model for each image. And then be able to understand exactly in three dimensions what's going on. You know, are the electrodes peeling off? Are there, sort of, bubbles being formed? Things like that. And yeah, so that's one of the limits of tomography where you really need to collect all these images. So for dynamic experiments, that's quite a limiting factor.

Ann Mossop: And so with that kind of approach, how well is that working?

Patrick Tung: So it works, there's, there's examples in the medical field. At the moment, I'm trying to develop that. I think not only would it be applicable for batteries, it could be applicable for all these other different applications as well.

Ann Mossop: So effectively, you'd be working at a much more efficient way to do the kind of scanning you want. Because each time you want to look at something, you would only need to take a handful of images rather than this incredibly detailed…

Patrick Tung: exactly.

Ann Mossop: … slice upon slice upon slice.

Patrick Tung: And that'll really give it a pathway for you to scan just thousands or millions of batteries and quickly check which ones are good. And then use those same AI algorithms to then also, maybe you can pinpoint defects and things like that inside and then automatically…

Ann Mossop: Pull them out.

Patrick Tung: Pull them out of the conveyor belt. And yeah, so at the moment, the way to do it is to, to physically connect to the battery and do tests on it. And you can imagine that's not super feasible… for millions of batteries.

Ann Mossop: Well, you’ve shown us a battery, that's, you know, I don't know, maybe 10 centimetres long, and that there’s thousands of them in a car. So yeah, yeah. In an individual car.

Patrick Tung: Yeah, you don’t know which ones are bad! Some are bad, some are good.

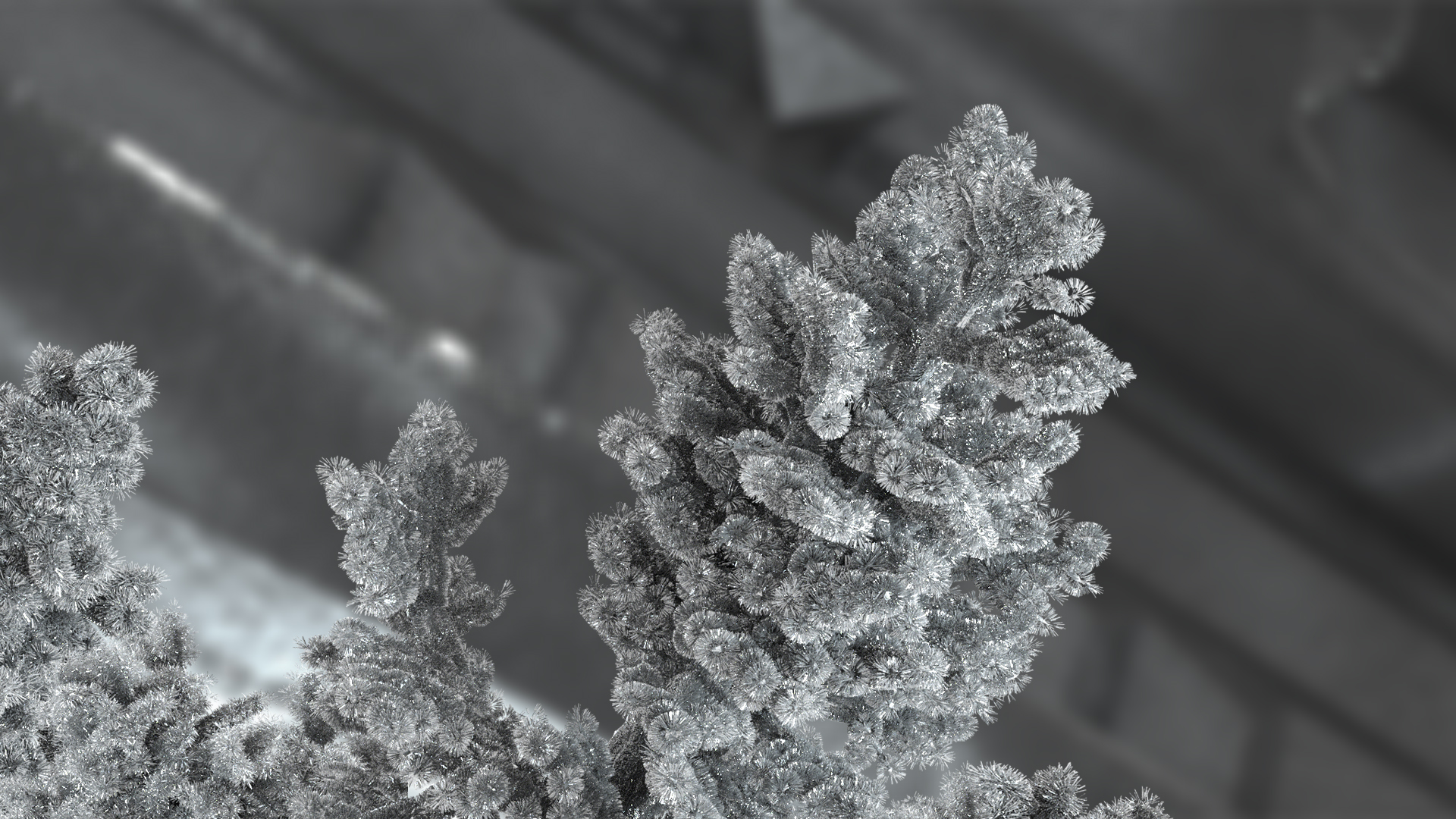

Ann Mossop: And I must just describe it, actually, because the image that Patrick has shown in the video of his talk, which is about a structure inside batteries, which is actually a destructive structure, called dendrite, is incredibly beautiful. It's like, it's like silvery snowflakes, or some kind of thing like that. So it's really interesting to see. So I'm just really interested in this, when you say that that's what you're working on, getting AI to do some of that, that important work. When you're doing that, what are you doing? You're going into the office, you're going into the lab where you have all of this amazing equipment, but you're sitting at a computer?

Patrick Tung: Yes, I'm sitting at a computer, a very powerful computer, which you really need. So they can sort of hold all this information. Right? So yeah, that's one of the limiting factors, you do need a relatively a lot of…

Ann Mossop: Computing power.

Patrick Tung: Yeah, but at least you know, we have enough money to, to buy some fairly decent hardware. Yeah, and, and, I always think about this, it’s not super interesting, I'm gonna give you a day in the life…

Ann Mossop: Well I don’t know! This is what's interesting is, I mean, it's very interesting to talk to you about your work, because in your talk, in the video version of your talk, people could see what a tomography image looks like. But I think particularly for people outside the field of science, there's such a huge range in the way people spend their time. And but but when you drill down, a lot of these fields now, it's, okay, it's a mixture between some practical work, but it's also it's a lot of coding, it's a lot of programming work of different kinds, it's a lot of streaming that through, so I just wondered…

Patrick Tung: So, I'd say 5% of my time would actually be in the lab to actually get the data. Maybe more if you're doing some more complex stuff, where you really need to set some environments up. But if you're just doing a scan, you sort of set it and forget it. But yeah, most of the time was actually doing the data analysis or getting the data, trying to find out what's important, what are you looking for. And then you know, presenting it in a way that's very nice. And, yeah, sitting in front of a computer, really. Looking at pretty images…

Ann Mossop: Pretty images of sinister structures!

Patrick Tung: Of sinister structures. Which are super cool.

Ann Mossop: So this kind of technology, if we're seeing it applied at large scale across a range of different sectors, whether it's, you know, computing or electric vehicles, or any kind of thing that depends on energy storage, how could it work in the future? Is it something where somebody might set up a company doing that? Or where manufacturers might take back their products? And they might need that expertise in house?

Patrick Tung: Yeah, I think it could go many ways. I guess it also depends on government regulations and putting the responsibility on the company to sort of be responsible for the whole lifecycle of the battery. But yeah, there's companies that do diagnostics of batteries, for Second Life purposes. But it could also potentially be beneficial for the company, because then they really extract every bit of usefulness out of that battery. Say if they, if they sell it to you, and they technically still own it, or something like that, then they could, you know, incorporate this technology to be able to then sell it off for other applications. And then that way, it's a real financial benefit for them, because they're really extracting every dollar.

Ann Mossop: Well, they've got an incentive to try and do that.

Patrick Tung: Exactly. Yeah, so I think that's really usually the best way for these, kind of, green solutions to happen, right? For it to be incentivised by the company.

Ann Mossop: And potentially for it to be built in from the very beginning. The understanding that, when we're building this product, we'll also be seeing it again. So that it's kind of easier, easier to do that.

Patrick Tung: So that's happening with, I think, I can't remember the name of the company, in California, where they're sort of discussing with the manufacturers of the cars to have the diagnostic tests installed into the car already. So as you're driving, you have real time knowledge of the health of the battery. But then, I guess, tomography does have that advantage where you can really see inside what's going on, because that's stuff, you really, you're just sort of testing the…

Ann Mossop: Does it work? Does it not work?

Patrick Tung: Exactly. Like, the numbers, with tomography, you really can see all the defects or all the physical attributes that would contribute to the properties of the battery?

Ann Mossop: Well, it seems like this is a technology and a technique that has huge potential to make sure that we make the best of materials. Thanks so much for coming and telling us about it.

Patrick Tung: Thank you very much Ann.

Ann Mossop: What comes next? is produced by the UNSW Center for Ideas. With music composition by Lana Zacharia and editing by Bryce Halladay. For more information, visit centreideas.com, and don't forget to subscribe wherever you get your podcasts.

Image Gallery

-

1/3

-

2/3

-

3/3

Patrick Tung

Dr Patrick Tung is a postdoctoral fellow at the Micro-CT Tyree Facility as part of the Mark Wainwright Analytical Centre at UNSW Sydney. Patrick completed his PhD in the School of Materials Science and Engineering in the Faculty of Engineering, focusing on the disordered atomic structures in piezoelectric materials using X-ray diffraction, and also won the UNSW Three Minute Thesis competition in 2016. His research has taken him to Czech Republic where he developed advanced neutron grain reconstruction methods as part of the commissioning of the European Spallation Source. Currently, his main research areas are in using X-rays to understand the relationship between the nano and micro-structure of materials and their resulting properties.